Technologies

Technology of Plasma-CVD

The deposition of diamond-like carbon or silicon carbide is performed by means of low-pressure plasmas. The typical pressure ranges from 1 to 100 Pa. The Plasma is a mixture of electrons, ions, neutral atoms and molecules. The energy needed for the creation of the plasma is delivered by plasma-sources developed by PT&B. These sources employ either dc or mid-frequency electrical energy. As a consequence of electron impact, molecules like hydrocarbons or silanes are cracked within the plasma. The resulting molecular radicals or ions reaching the good to be coated and form a solid film at the surface. This process can be supported by a bias voltage (also dc or mf-type) applied to the good. The technology described is referred to as “plasma enhanced chemical vapor deposition” and known under the abbreviations PCVD, PECVD or PACVD.

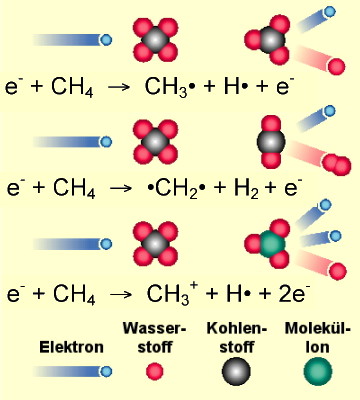

Decomposition of methane

Energetic electrons created by electrical fields hit on molecules. The molecule is decomposed in fragments like radicals or ions. The processes schematically shown are described by reactions of plasma-chemistry.

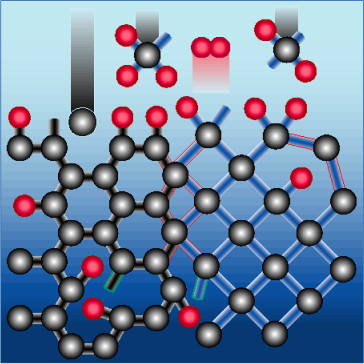

Growth of the DLC coating

- Carbon ions (“long tailed”) hitting the surface with high energies stick immediately and are incorporated.

- Neutrals (molecule radicals - “short tailed”) hitting with low energy and move along the surface. Incorporation takes place after chemical reactions with free bonds. Simplified chemical reaction: -CH2-(gas) --> C(sol) + H2.

Simplified structure of DLC

- Graphite-like (sp2) bonds - black

- Diamond-like (sp3) bonds - blue

- Bonds are distorted, compressed or stretch (red frame)

- Bonds are unsaturated (“dangling bonds” - green frame)

- Hydrogen is chemically bonded in the bulk and covers (terminates) the surface