Properties

The Properties of SilCor® CrN

- Chemical Composition

- Underlayer: Chromium

- Main Layer: Cr, N (optimized ratio), O

- Deposition Technology

- Sputtering (specific method of physical vapor deposition - PVD)

- Deposition temperature: T= 200 oC

- Mechanical Properties

- Coating thickness: 1 - 10 µm, typical thickness 3 µm

- Surface roughness (rms): typical 0,07 µm

- Universal hardness: UH = 24 GPa

- Vickers hardness: HV0.01 = 1900

- Young's modulus: E = 250 GPa

- Elastische Deformation: WE/P = 55 %

- Mechanical stress (tensile): s = - 0,5 GPa

- Coefficient of frication (dry against steel): µ = 0,56

- Specific gravity: rho = 6,1 g/cm3

- Physical and Chemical Properties

- Specific resistivity: 10-2 Ωcm

- Morphology: nanocrystalline, grain size about 20 nm

- Temperature stability: up to 700 oC

- Chemical resistance mainly against acids, leaches, salts and oxidizing media

- De-coating by means of wet-chemistry

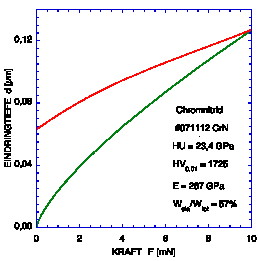

- Measurement of mechanical hardness:

- A viewgraph is shown of the load-dependent penetration depth for a Vickers-type diamond with increasing load (green line). After reducing the load to zero (red line - decreasing load) there is still penetration due to a plastic deformation of the coating. From this measurement the macroscopic material parameters can be computed, which are given in the inset for the specific film.

Note: The indicated values refer to measurements of selected, typical sample test specimens. Because of geometric plasma effects the measured characteristics can vary in particular as a function of the size of the substrates. For the exact determination of the coating characteristics the actual coating goods (substrates) of the customer has to be used.