DLC Carbon

DLC - Applications 2

Valves | Fittings | Seal Elements | Chemical Industry

For these applications the high chemical inertness of the DLC coating is useful. Extreme environmental conditions like hot acid vapors are able to quickly destroy even highly alloyed steel. Valve balls, valve seats, flaps or slidegate valves need smaller moving forces, which leads to smaller dimensions of the drives because of the reduced friction by the SilCor® DLC layer. Also axial face seals profit from the small friction value and the high hardness of the diamond-like layer.

Design: Decoration and Consumer Durable Goods

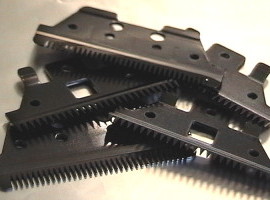

Watch cases or rings with polished surfaces and a SilCor® diamond-like carbon layer appear reflecting, shining black. The endurable black coating underlines the high value and the noble appearance of the product. The biocompatible DLC coating prevents allergic reactions, which can result in particular from intensive skin contact with different metals. Electric shaver components, knifes and shears keep its value in use a multiple longer owing to the DLC.

Automobile industry

Because of its excellent properties diamond-like carbon is suitable for a multiplicity of automobile applications. However, the high-quality DLC coatings are used only for a few applications - for example fuel injection systems. The reason for this is the relatively high costs, which still hinder several applications for automotive mass-market applications. SilCor® DLC layers are already used in different components for car racing (Formula 1, German DTM Championship). The coating is applied to tappets, steering gear racks, springs, pistons and others.

Tools

A broad variety of primary shaping tools, forming tools and cutting tools are coated with diamond-like coatings. Principal purpose is mostly the prevention of material adhesions (DLC as non-adhesive layer) in combination with abrasion protection. The materials in contact with these tools are typically plastic melts (injection molding) and powders (e. g. tablet compacting) in the field of primary shaping and light metals (e. g. aluminum) in the fields of forming and cutting.