Metallic Coatings

Aluminum Thin Films

Sputtered aluminum layers have a high reflectivity in the visible spectral range of over 90% (with a maximum of 95%) and therefore appear silvery white. In the infrared spectral range, the reflectivity of the aluminum layers increases to values close to 100%. Therefore, aluminum is in principle very well suited as a layer for mirrors in these wavelength ranges. However, the subsequent oxidation of the freshly deposited layers leads to a significant deterioration of the reflectivity. For this reason, PT&B offers various passivation layers for protection against environmental influences. Without breaking of the vacuum, in situ aluminum oxide or aluminum nitride can be applied by means of reactive sputtering (PVD). Alternatively, in other reactors, transparent passivation layers of silicon oxide (SiO 2), silicon nitride (Si 3 N 4) or silicon carbide (SiC) can be deposited onto the aluminum by means of plasma chemical vapor deposition (PCVD).

Aluminum layers deposited by sputtering (PVD) achieve a very low resistivity of 2 10-8 Ohm m, which is close to the value of the massive metal. However, this value is also reduced by the subsequent oxidation. An additional passivation layer is therefore advantageous - as well as in optical coatings.

The microstructure of sputtered aluminum films is determined in particular by the low melting point of the metal on the one hand and by its lower atomic mass in comparison to the sputtering gas argon. In the following, results of structural investigations by means of X-ray methods on thin aluminum layers are shown.

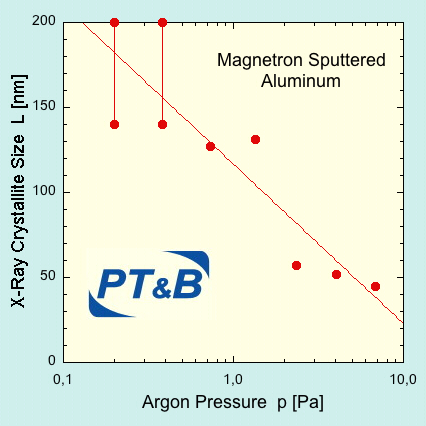

By means of X-ray wide-angle scattering (WAXS) the average crystallite size in aluminum layers is determined. As a function of the pressure during sputtering, the the crystal size increases logarithmically with the decreasing pressure. For the smallest pressures, the size of the crystallites is above the detectable maximum value of 140 nm.

(The layer thickness is 150 nm, the deposition temperature was T = 50ºC)

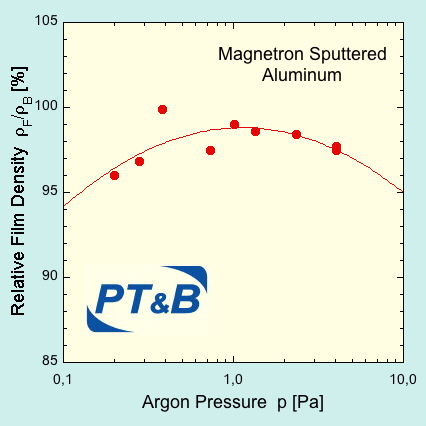

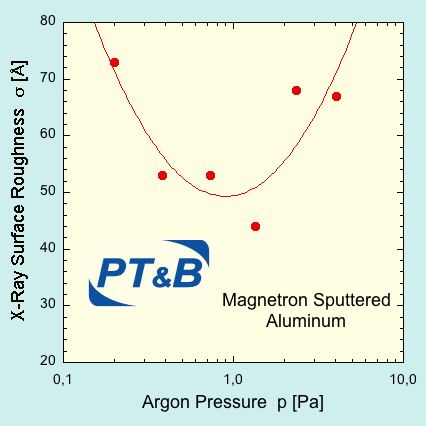

The density of the films of aluminum (compared to the solid metal) and the average roughness of the surface are determined by X-ray reflectometry (SAXS) and are shown below. The density of the aluminum layers shows a weak dependence on the argon pressure during the sputter deposition with a maximum at about 1 Pa (left). Aluminum layers have a comparatively high roughness of the film surface, whereby a minimum can be observed at an argon pressure of about 1 Pa (right).