Silicon Carbide

Applications of Silicon Carbide SilCor®SiC

The coatings show their unique good characteristics at all processes combined with unwanted adhesion or wetting of surfaces by liquid substances. Due to the improved coating thickness up to 50 micrometers also surfaces of minor quality become electrical insulating and highly corrosion resistant.

Anti-Sticking | Anti-Fouling | Hydrophobic Coatings

Alloying DLC (carbon) coatings with silicon results in a strong decrease of the surface energy down to typical values of 22 mN/m. These low values prevent surfaces from the attachment with severe molecules. The effect is in general also referred to as anti-adhesion coating. In plastics processing industry the anti-sticking effect is used to prevent plastics from the adhesion to molding forms and cores. The forces for de-forming parts from the tools are reduced. In additon, the surface quality of plastic goods produced increases. Due to the hardness of the SiC, the tool lifetime is increased. Because of the negligible roughness of the silicon carbide coating, the surface quality of the tools is sustained after the coating process. The coating is suitable for molds for injection and blow molding. For food industry SiC can be applied to reduce sticking of dairy, pastry and meat products. The SilCor®SiC coating shows non-wetting behavior for various polar and non-polar liquids. Due to the hydrophobic properties, dew formation can be drastically reduced.

Anti-Corrosion | Anti-Fretting Coatings

These features are of great importance for chemical technology and semiconductor industries. On one side SiC delivers protection of metallic parts from highly aggressive media used in chemistry. Second, silicon carbide films are useful to avoid contamination of sensitive, high purity media as powders, gases or liquids. In medical technology these inert coatings are applied to permanent implants and prostheses or temporary interventional and diagnostic devices. Note that silicon carbide coatings are fully biocompatible.

Insulating Layers | Micro Structuring

Insulating Layers | Micro Structuring High electrically insulating SiC films are used in sensors or electrode systems as a dielectric material. The films can be processed by laser to form specific surface patterns and structures.

Diffusion Barriers

A well-known disadvantage of plastic materials is the high diffusion of water vapor. Silicon carbide films even in the sub micron range show a water vapor diffusion value as low as a few mg/m^2 per day. Therefore, SilCor®SiC films are a suitable water diffusion barrier for plastics.

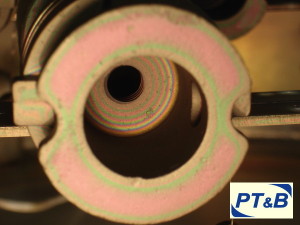

Bushing for a chemical apparatus coated with a SilCor®SiC silicon carbide film.

According to specific requirements inner coatings down to 5 mm diameter can be performed.