About Silicon Carbide

Modifications of DLC by Adding Silicon

Various application of DLC are restricted by its physical properties. These restrictions can be overcome by alloying it with silicon. There are several reasons to use silicon-carbon alloy films instead of DLC:

- An increased thermal stability - up to 500 deg C working temperature

- Improved optical transmission throughout the visible spectrum (dependent on film thickness)

- High chemical resistance against oxidation in air, other gases and liquids

- Long term stable coefficient of friction in humid air and aqueous liquids

- Excellent electrical insulation due to high specific resistivity

- Required film thickness above 3µm (maximum 50µm)

According to the type and amount of electrical energy supplied to the PCVD-process, the deposition occurs at a temperature in the range between 50 and 400 deg Celsius. In principle, a higher deposition temperature results in coatings of increased hardness and lowered hydrogen content - if the other process parameters are unchanged. SilCor®SiC silicon carbide films are suitable for inner coatings of tubes and bore holes. The maximum aspect ratio, which is possible to be coated, depends on the absolute value of the diameter.

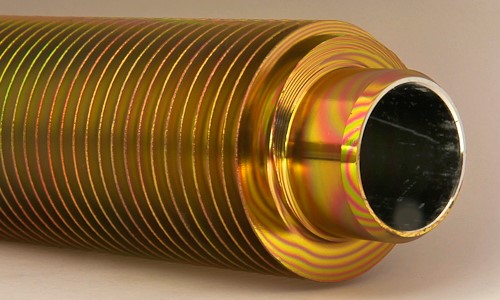

Photo: SilCor®SiC silicon carbide coated heat exchanger made of aluminum.